Piping systems are ubiquitous in modern industrial production and daily life, from water supply and heating to natural gas transportation. With the passage of time, pipelines may have leakage problems, which not only leads to waste of resources, but also may cause environmental pollution and safety hazards. Therefore, regular inspection with pipeline leak detector has become a necessary maintenance task. In this article, we will briefly introduce this type of equipment and provide some suggestions for purchase.

Introduction of pipeline leak detector

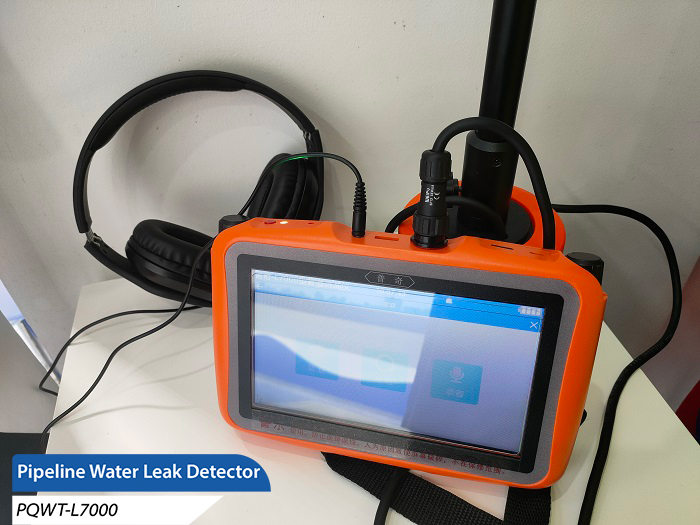

The pipeline leak detector is a professional device used to detect leaks in various pipelines (including but not limited to water pipelines, natural gas pipelines, oil pipelines, etc.). It usually adopts acoustic wave technology, infrared detection, gas induction and other methods to locate the leakage point, which is characterized by high sensitivity and accuracy.

Main types and technical characteristics

Acoustic Leak Detector: Determine the location of leakage by capturing the sound or vibration generated during leakage, applicable to pipelines made of various materials.

Infrared Thermal Imaging Camera: Utilizes infrared imaging technology to detect temperature differences, thus discovering the leakage area, especially suitable for pipelines that are not easy to contact directly.

Gas detector: For pipelines conveying gases, it can be used to detect changes in the concentration of specific gases to determine whether a leak has occurred.

Electronic stethoscope: Similar to a medical stethoscope, but more sophisticated, it can amplify the sound signal inside the pipeline to help technicians determine the specific location of the leak.

Selection considerations

1. Application areas: different industries have different needs for leak detectors, such as municipal water supply, petrochemical and other focus.

2. Precision requirements: according to the actual needs of the selection of the appropriate level of precision, too high a precision may increase the cost and not necessary.

3. Convenience of operation: Considering the complexity of the field work, it will be more practical to choose instruments that are easy to carry and simple to operate.

4. After-sales service: good after-sales support and service can be timely in the emergence of problems to be resolved, to ensure the long-term stability of the equipment.

5. Budget constraints: pipeline leak detector has a wide range of prices, from a few thousand dollars to hundreds of thousands of dollars, according to their own budget to make a reasonable choice.

Although we do not give a specific price range, but through the above analysis can be seen, choose a suitable pipeline leak detector need to consider a number of factors. It is recommended to do sufficient market research and consult professionals before purchase to ensure that the selected equipment can meet the actual needs, but also has a high cost-effective.