Water pipeline leak detection equipment is a professional tool designed to detect and locate leaks within water pipeline systems.Proper use of this equipment not only facilitates timely discovery and repair of leaks but also effectively prevents water wastage and potential damages.Below is a comprehensive guide on how to use water pipeline leak detection equipment.

I.Preliminary Preparations

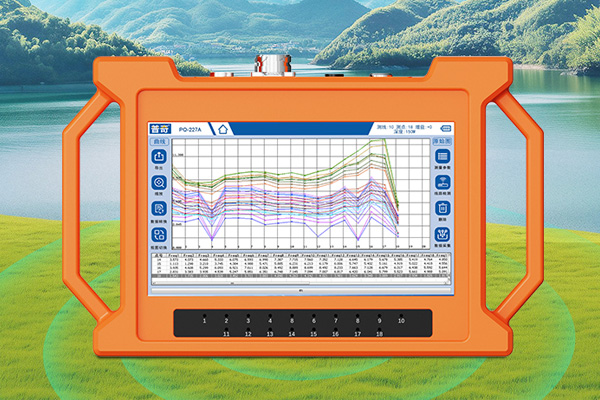

1.Equipment Check:Before using the water pipeline leak detection equipment,ensure that it is in good working condition.Check the battery level for sufficient power,the sensitivity of the sensors,the clarity and intactness of the display screen,and the integrity of accessories such as cables and headphones.

2.Pipeline Information Understanding:Prior to detection,gather information about the water pipeline's routing,material,burial depth,etc.This information helps narrow down the detection scope and enhances efficiency.

3.Auxiliary Tools Preparation:Apart from the leak detection equipment,prepare auxiliary tools such as dry towels,tissues,pens,and paper for recording and marking during the detection process.

II.Operating Steps

1.Equipment Connection:Connect the sensor or probe of the water pipeline leak detection equipment to the relevant pipeline section at the test point.Choose an appropriate connection method based on actual needs,such as threaded connection or clamp fixation.Ensure a secure connection to prevent air leaks from affecting detection results.

2.Detection Mode Setting:Select the appropriate detection mode and parameter settings according to the specific equipment and model in use.Water pipeline leak detection equipment typically offers various detection modes such as sound detection,pressure detection,and thermal imaging.Choose the most suitable mode based on the site conditions.

3.Detection Initiation:Follow the equipment's operating instructions to start leak detection.Depending on the selected detection mode,assess the presence of leaks by listening to sounds,observing pressure changes,or analyzing thermal imaging images.

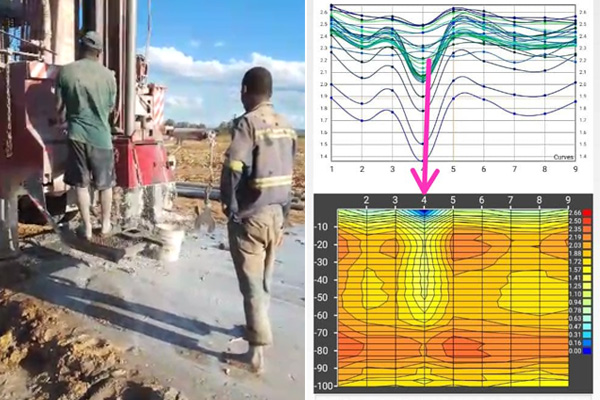

4.Leak Point Localization:When the detection equipment triggers an alarm,carefully identify the sound characteristics and analyze the signal strength on the display screen.Conduct a step-by-step inspection along the pipeline until the exact location of the leak point is found.Distinguish between other interfering signals,such as water flow sounds and gas leakage sounds.

5.Recording and Analysis:After locating the leak point,mark its position using auxiliary tools like pens and paper.Simultaneously,record relevant data during the detection process,such as the leak point's location and pressure changes.Analyze and assess the leak situation based on these data to determine a repair plan.

III.Precautions

1.Safe Operation:When using water pipeline leak detection equipment,adhere to relevant safety regulations and wear necessary protective gear.Avoid detection in high-pressure,high-temperature,or toxic and hazardous environments.

2.Interference Avoidance:During detection,be mindful of avoiding interference sources such as loud noise and strong electromagnetic fields,which may affect the accuracy of detection results.

3.Regular Maintenance:As precision instruments,water pipeline leak detection equipment requires regular maintenance and care.After use,promptly clean the equipment's surface of dirt and dust to keep it clean.Additionally,periodically check the equipment's performance and accuracy,and repair or replace components as needed.

4.Comprehensive Judgment:The detection results from leak detection equipment only provide the approximate location of leak points.Comprehensive judgment based on actual conditions is necessary.For example,for ground leaks,a combined analysis of ground material,pipeline layout,and other factors may be required.