In modern life,pipeline systems are widely used in various fields,from household water supply and drainage to material transportation in industrial facilities.The normal operation of pipelines is crucial.However,pipeline leaks occur from time to time,not only causing water waste but also potentially leading to safety hazards and property damage.To accurately locate leaks,people often rely on pipeline leak detectors.But how reliable are these devices in detecting leak points?

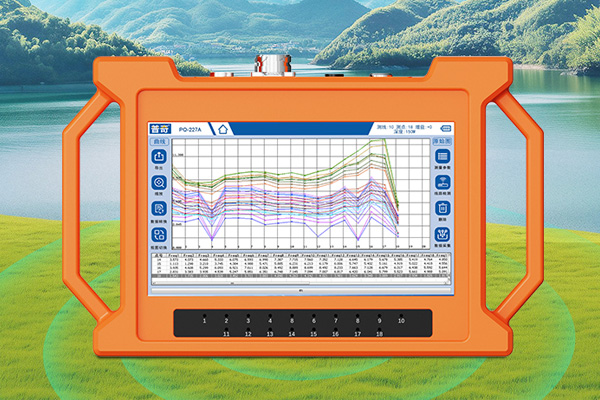

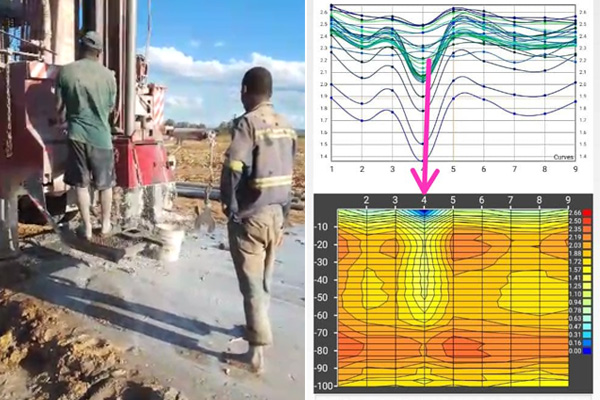

Pipeline leak detectors operate based on technologies such as acoustics,pressure changes,or electromagnetic waves.Taking the common acoustic leak detector as an example,when a pipeline leaks,the water flow generates vibrations at the leak point,producing sound waves of specific frequencies.The detector captures these sound signals through highly sensitive sensors and converts them into electrical signals for analysis.By analyzing parameters such as sound intensity,frequency,and propagation characteristics,the detector can roughly determine the location of the leak.

In terms of practical application,pipeline leak detectors have demonstrated high reliability in many cases.For buried pipelines,traditional detection methods often require extensive excavation,consuming significant manpower,resources,and time,while potentially causing environmental damage.In contrast,using a leak detector,technicians can perform non-invasive detection above ground,quickly identifying suspected leak areas and greatly improving efficiency.For instance,in the detection of water supply pipelines in older residential areas,leak detectors have successfully helped workers accurately locate multiple leak points,avoiding unnecessary large-scale repairs and minimizing disruption to residents'lives.

However,pipeline leak detectors are not infallible and have certain limitations.First,environmental noise is a critical factor affecting their accuracy.In noisy industrial environments or areas with heavy traffic,external noise interference may mask the sound of leaks,leading to misjudgment or failure to detect accurately.Second,factors such as pipeline material,diameter,and internal medium also influence detection results.For example,in large-diameter pipelines,leak sounds travel farther and are more prone to attenuation,potentially increasing the difficulty of localization.Similarly,for pipelines made of special materials,the detector's signals may not effectively penetrate or identify leaks.Additionally,if the water pressure inside the pipeline is too low,the sound generated by the leak may be too weak,posing challenges for detection.

To enhance the reliability of pipeline leak detectors,certain precautions should be taken during use.Operators should possess professional skills and extensive experience to correctly use the detector and analyze the data appropriately.Moreover,combining multiple detection methods can provide cross-verification,improving accuracy.For example,using an acoustic leak detector alongside pressure testing to observe changes in pipeline pressure can further confirm the leak location.

In conclusion,pipeline leak detectors are highly reliable for locating leaks but do have some limitations.In practical applications,by selecting and using the detector correctly and integrating it with other detection methods,the accuracy of detection can be significantly improved.This ensures timely repair of pipeline leaks,supporting the safe and stable operation of pipeline systems.