Core Principles of Pipeline Leak Detectors

Main Types and Characteristics of Pipeline Leak Detection Instruments

Application Scenarios and Selection Suggestions for Pipeline Leak Detectors

Technological Development Trends

Leakage in underground water pipelines not only results in the wastage of water resources but may also trigger issues such as ground subsidence and environmental pollution.With technological advancements,various pipeline leak detectors and methods have been developed for precise leak localization.This article provides a comprehensive analysis of pipeline leak detection,covering detection principles,instrument types,application scenarios,and development trends.

I.Core Principles of Pipeline Leak Detectors

1.Acoustic/Vibration Detection Method

When a water pipeline leaks,high-pressure water striking the pipe wall and surrounding medium(e.g.,soil,bricks)generates specific frequency noise and vibration signals.These signals propagate through the pipe or soil to the ground and are received by high-sensitivity sensors(e.g.,vibration pickups).After signal amplification,filtering,and spectral analysis,the leak location can be determined.The signals are strongest near the leak and weaken with distance.By comparing signal intensities at different locations,the leak position can be pinpointed.

Technical Advantages:Low cost,easy operation,suitable for both metal and nonmetallic pipes.

Limitations:Susceptible to environmental noise interference;digital filtering technology(e.g.,spectral separation function of Puqi PQWT-L7000 pipeline leak detector)is required to enhance accuracy.

2.Infrared Thermography Method

Water leaks can cause abnormal temperatures in the surrounding environment(e.g.,local cooling due to increased soil moisture).Infrared thermography cameras capture temperature differences to generate thermal maps,identifying potential leak points.

Application Scenarios:Non-destructive testing in enclosed spaces such as walls and floors.

Limitations:High equipment costs and significant impact from ambient temperature differences.

3.Gas Tracer Method

Tracer gases such as helium or nitrogen are injected into the pipeline.The gas escapes at leak points to the surface,where high-sensitivity gas detectors track concentration peaks to locate leaks.

Advantages:Suitable for complex piping networks and concealed leak detection.

Limitations:Requires professional operation and may be affected by wind direction.

4.Electromagnetic Detection Method

Electromagnetic signals are emitted towards the pipeline,and reflections or attenuations are analyzed to assess pipeline integrity and leak locations.

Applicability:More effective for metal pipes but has limited penetration for nonmetallic pipes.

II.Main Types and Characteristics of Pipeline Leak Detection Instruments

1.Acoustic/Vibration Leak Detectors

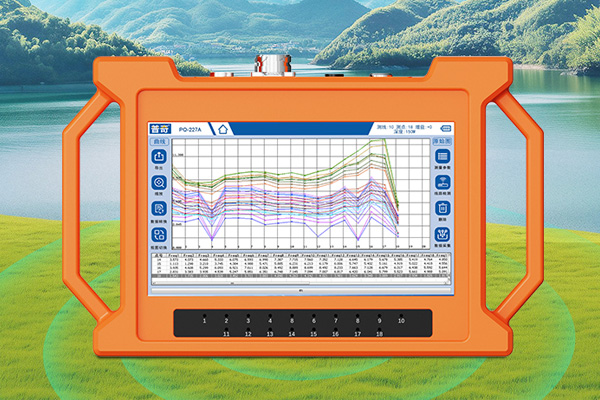

Principle:Combines human auditory discrimination with electronic amplification technology.Water leak acoustic waves are collected through microphones,and interference noise is separated using filters(e.g.,digital signal processing of Puqi PQWT-L7000).

Applications:Valve and bolt listening(pre-localization)and ground listening(precise localization),with the latter detecting signal intensity peaks at intervals of 0.5 to 2 meters along the pipeline route.

2.Multi-Probe Leak Detection Systems

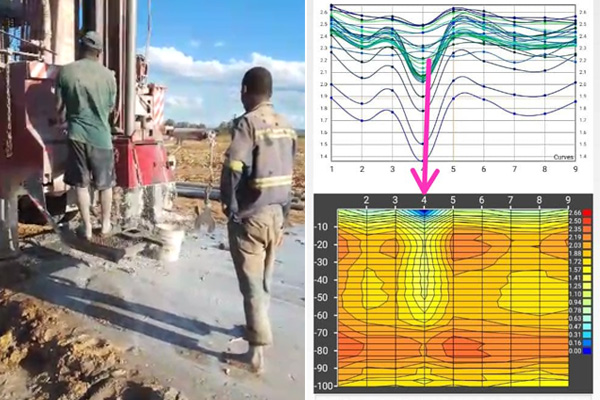

Principle:Multiple sensors synchronously collect data,and leak locations are calculated based on differences in acoustic wave propagation times,suitable for long-distance pipelines.

Advantages:High positioning accuracy and strong anti-interference capabilities.

3.Ground Penetrating Radar(GPR)

Principle:Emits high-frequency electromagnetic waves and analyzes reflected signals to detect underground structural anomalies(e.g.,voids,water-logged areas).

Applicability:Strong penetration,can detect nonmetallic pipes,but data interpretation requires professional expertise.

4.Resistive Leak Detectors

Principle:Utilizes the conductivity of water,monitoring current changes through electrodes to detect leaks.

Characteristics:Adjustable sensitivity,suitable for small pipes or localized detection.

III.Application Scenarios and Selection Suggestions for Pipeline Leak Detectors

1.Urban Water Supply Systems

Acoustic detection methods are widely used due to their low cost and efficiency.Combined with correlation instruments,leaks can be rapidly located,reducing excavation losses.

2.Industrial Pipelines

Instruments with strong anti-interference capabilities(e.g.,electromagnetic or gas tracer methods)are required for leak detection in complex media(oil,chemicals).

3.Agricultural Irrigation Systems

Infrared detection or resistive instruments are more suitable for rapid screening of shallow underground pipes.

Selection Points:

·Environmental Adaptability:Acoustic methods are preferred in urban environments,while radar or gas tracer methods are considered for complex terrains.

·Precision Requirements:Multi-probe systems or spectral analyzers are selected for high-precision scenarios.

·Budget Constraints:Low-cost scenarios can opt for acoustic leak detectors or resistive devices.

IV.Technological Development Trends

1.Intelligence and Automation

New-generation instruments integrate AI algorithms for real-time noise spectrum analysis and automatic marking of suspected leak points,reducing manual misjudgments.

2.Multi-Technology Fusion

Composite detection modes combining acoustic,infrared,and radar enhance accuracy in complex environments.

3.Remote Monitoring and Early Warning

The application of IoT technology enables instruments to support remote data transmission for real-time pipeline condition monitoring.

Leak detection in underground water pipelines requires selecting appropriate methods based on factors such as pipe material,burial depth,and ambient noise.Acoustic methods remain mainstream,but the supplementation of infrared,gas tracer,and other technologies can enhance overall efficiency.In the future,with the development of intelligence and multi-technology fusion,leak detection will become more precise and efficient,providing reliable support for the maintenance of urban infrastructure.