In the operation and maintenance of heating systems, the detection of pipeline leaks is crucial. Precise and efficient water pipe detectors can help heating enterprises promptly identify and repair leakage points, ensuring the stable operation of the heating system and reducing energy waste and economic losses. This article will introduce in detail the types of water pipe detectors commonly used by heating enterprises, providing a comprehensive reference for your selection of water pipe detectors.

Acoustic Water Pipe Detector

The acoustic water pipe detector is one of the most widely used leak detection devices in heating enterprises. Its working principle is based on the specific frequency of sound waves generated when water is ejected from a leak point under pressure in the pipeline. High-sensitivity sensors collect these sound wave signals, which are then amplified, filtered, and analyzed by the main unit. Operators can then determine the leak location based on the signal characteristics.

The advantages of acoustic water pipe detectors are significant. They can detect leaks without damaging the pipeline structure, minimizing the impact on the pipeline system. With high detection sensitivity, they can detect minute leak points, effectively avoiding large-scale failures caused by untreated small leaks. Operation is relatively simple, and technicians who have undergone professional training can quickly get started and become proficient.

However, acoustic water pipe detectors also have certain limitations. In areas with high ambient noise, such as busy streets and factory workshops, external noise interference may affect the accuracy of detection results. Additionally, for pipelines buried deeply underground, pipelines with special materials, or situations where the surrounding medium significantly hinders sound wave propagation, the sound wave signals attenuate severely, limiting detection depth and accuracy.

Gas Water Pipe Detector

Gas water pipe detectors are mainly used to detect leaks of gaseous media in heating systems. Common gas water pipe detectors include helium leak detectors. Their principle involves utilizing the high permeability and easy detectability of specific gases like helium. A mixture of gases containing helium is injected into the heating pipeline system. If there is a leak point, helium will escape from the leak point, and high-precision sensors detect changes in helium concentration to determine the leak location.

The advantages of gas water pipe detectors lie in their extremely high detection accuracy, capable of detecting extremely minute leak points. They are particularly suitable for detecting critical components and systems with high sealing requirements, such as core components and precision valves of some high-end heating equipment. Moreover, they are unaffected by pipeline materials and the surrounding environment and can be used in various complex operating conditions.

However, gas water pipe detectors also have shortcomings. Firstly, the detection cost is relatively high, both in terms of the procurement cost of gases like helium and the price of the instrument itself. Secondly, the detection process is complex, requiring special filling treatment of the pipeline system and high technical standards and operational specifications for operators.

Thermal Imaging Water Pipe Detector

Thermal imaging water pipe detectors detect leak points in heating pipelines by utilizing temperature distribution differences on the surface of the detected object. When a pipeline leaks, the outflow of hot water causes changes in the temperature of the surrounding medium. The thermal imaging water pipe detector converts this temperature change into a visual thermal image through infrared thermal imaging technology. Technicians can determine the approximate location of the leak point based on the position and shape of the abnormal temperature area in the thermal image.

The outstanding advantage of thermal imaging water pipe detectors is their fast detection speed, enabling quick scanning of large areas and rapid localization of potential leak hotspots. The non-contact detection method makes operation convenient, without the need for direct contact with the pipeline, avoiding damage to the pipeline or interference with its operation. At the same time, it can intuitively display temperature abnormalities, facilitating analysis and judgment by technicians.

However, the accuracy of thermal imaging water pipe detectors is relatively lower compared to acoustic and gas water pipe detectors, and they may not be accurate enough for detecting minute leak points. Their detection results are susceptible to factors such as ambient temperature and wind speed, and detection effectiveness can be significantly reduced under harsh climatic conditions. Moreover, thermal imaging water pipe detectors are relatively expensive, requiring a significant investment in equipment.

Correlation Instrument

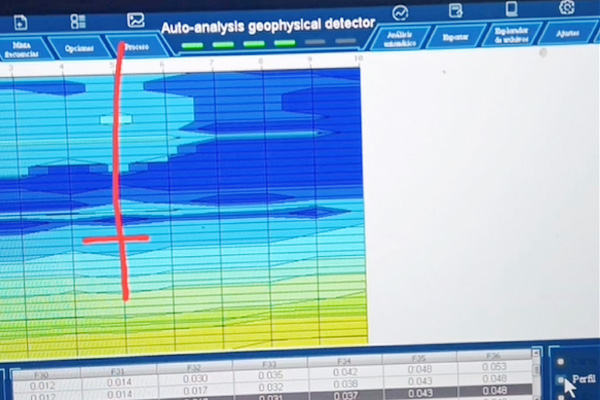

A correlation instrument is a specialized device for leak detection in long-distance pipelines. It installs sensors at different locations along the pipeline, simultaneously collects sound wave signals within the pipeline, and uses correlation algorithms to analyze the propagation time difference of signals between different sensors, thereby accurately calculating the location of the leak point.

The biggest advantage of correlation instruments lies in their extremely high accuracy and reliability in leak detection for long-distance and complex pipeline networks. They can effectively eliminate ambient noise interference and quickly and accurately locate leak points even in situations with numerous pipeline branches and complex layouts, greatly improving detection efficiency and reducing the scope and time of investigation.

However, the equipment cost of correlation instruments is high, requiring multiple sensors and professional data processing equipment, which results in a significant initial investment. Additionally, the operation and data analysis of correlation instruments require professional technicians, with high personnel requirements. The maintenance of the equipment is also complex, requiring regular calibration and maintenance to ensure detection accuracy.

In summary, when selecting water pipe detectors, heating enterprises should comprehensively consider various factors such as the characteristics of their pipeline systems, detection environments, budgets, and requirements for detection accuracy and efficiency. For routine inspections and regular leak detection of general heating pipeline networks, acoustic water pipe detectors are a more economical and practical choice. For critical areas with high sealing requirements or specific requirements for detecting minute leaks, gas water pipe detectors are more suitable. In scenarios requiring rapid screening of large areas for leak points or sensitivity to changes in pipeline surface temperature, thermal imaging water pipe detectors can excel. For leak detection in long-distance and complex pipeline networks, correlation instruments have unparalleled advantages. Only by reasonably selecting water pipe detectors based on actual needs can heating enterprises efficiently and accurately carry out pipeline leak detection work, ensuring the safe and stable operation of heating systems.