In our daily life, we may encounter various water leakage problems, which not only bring us inconvenience, but also may cause certain losses. In order to prevent the water leakage problem from further deteriorating, timely water leakage detection is very necessary. So, what are the steps of water leakage detection? Let's find out below.

1. Collect pipe data

Before carrying out water leakage detection, you first need to collect the drawings of the pipes to be detected and the data of the position water consumption. Enterprises will arrange for technicians who understand the location of the pipeline to visit the site, informing them of the plane location of the pipeline, the depth of burial, the material of the pipeline, the size of the pipe diameter and other relevant information. This information is very important for the subsequent testing work.

2. Surveying the surrounding environment of the regional pipeline network

Leakage detection, but also need to fully understand the specific situation of the site, including the survey of the surrounding environment of the pipe network, checking the auxiliary equipment, how much water consumption and the investigation of drainage conditions. These preparations can provide reference for the subsequent detection work to ensure the smooth progress of the detection work.

3. Detailed investigation of water leakage

In the detection area, 100% of the daytime directly on the area inside the hydrant, valve, water meter, open pipe listening, so as to obtain the leakage point to the pipeline sound waves, perceived leakage. Once the anomaly is detected, a very detailed registration is required for subsequent processing.

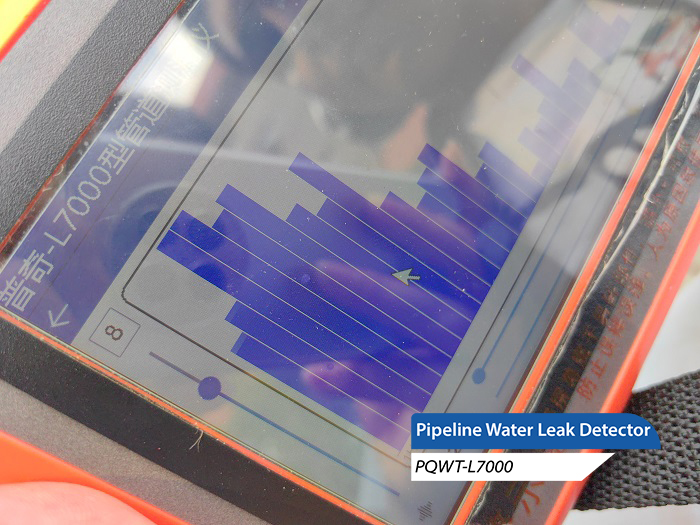

4.Listening sound detection

In the survey area above the pipeline, with a water leakage detector along the "S" type pipeline every 0.5 ~ 1.0m to listen to the sound. In the relatively stable water consumption, the surrounding environment is relatively quiet period for construction. This can be more accurate survey buried in the pavement under the pipeline leakage, and in the ground to mark the possible leakage of the place.

5. Tests related to piping input

For the relatively complex and abnormal leakage areas surveyed or places with noise interference, the relevant instruments can play a very big role. By automatically calculating the correlation peaks to find out where the leakage points are, leakage detection operations can be carried out without manual precision. The correlation analysis is completed to find out the direction and connection status of the target pipeline.

6.Confirmation and localization of leaks

For those found leaks or abnormal areas, it is necessary to organize skilled and experienced maintenance personnel to judge the abnormal situation and determine whether it is an abnormal water leak. If it is an abnormal water leak, then accurately locate the leak. This will allow repairers to better find the problem and improve repair efficiency.

7. Recheck the leak after repair

After completing the repair of the leak in the work area, conduct another leak test to find the correct location of the leak. If there are no abnormal leaks in the area, then the leak detection work is completely finished. This step is to make sure that the repair work has been completed thoroughly and that there are no missing problems.

8. Overall, water leak detection is a complex and important process. With the above steps, we can better understand the water leak and fix it in time. If you are experiencing a water leak, you may want to contact a professional water leak detector to inspect and fix it.