Heating pipe leakage is a common problem that not only affects the heating effect, but also brings unnecessary damage to your home. Therefore, it is very important to detect and fix the leakage problem in time. In this article, we will introduce the heating pipe leakage detection methods to help you quickly locate and solve the leakage problem.

First, the causes of water leakage and common parts

1. Pipe aging: after a long time of use, pipe wear, aging and other phenomena, resulting in water leakage.

2. Loose pipe connections: due to vibration or aging and other reasons, the pipe connections appear loose, resulting in water leakage.

3. Pipe rupture: due to high pressure or external impact, etc., the pipe rupture, resulting in water leakage.

Common water leakage parts:

1. Pipe connections: such as valves, flanges and other connections.

2. Pipe elbow: due to long-term pressure or vibration, the elbow is prone to cracks.

3. Pipeline openings: such as exhaust valves, relief valves and other parts.

Second, water leakage detection methods

1. Observation method: Observe whether the heating pipe has water drops, wet phenomenon, or close the valve after the pipeline whether the sound of water flow.

2. Touch method: check whether there is water seepage at the pipe connection by touching, or whether there is wetness on the surface of the pipe.

3. Auscultation method: use a stethoscope or ear close to the pipe, listen to whether there is water flow sound or bubble sound.

4. Pressure test method: in the case of the valve is closed, the pipeline is pressurized to test, observe whether the pressure drops. If it falls, it means that there is a water leak.

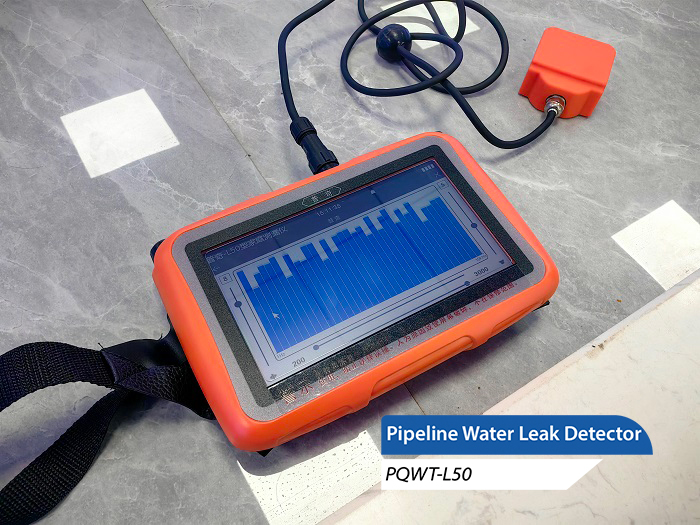

5. Professional instrument detection method: the use of professional water leakage detection equipment, you can more accurately locate the leakage location.

Third, water leakage repair steps

1. Close the valve: first of all, close the water source valve to prevent the water from continuing to spread.

2. Locate the leakage position: according to the detection method, locate the leakage position.

3. Cut off the leakage part: cut off the pipe above the leakage part to prevent the leakage from expanding.

4. Repair the leakage part: according to the cause and part of the leakage to take corresponding repair measures, such as replacing seals, welding cracks, etc..

5. Pressure test: After the repair is completed, pressure test the pipeline to ensure that there is no further leakage.

6. Open the valve: After confirming that there is no water leakage, open the valve and resume heating.

Preventive measures

1. Regular inspection: Regularly inspect the heating pipes and deal with any abnormalities in time.

2. Timely maintenance: once the leak is found, take timely measures to repair to avoid the problem from expanding.

3. Reasonable use: In the process of use, avoid excessive pressure or external impact on the pipeline.

4. Pay attention to maintenance: regular maintenance of the pipeline, such as cleaning, replacement of seals, etc., in order to extend the service life of the pipeline.

In short, it is very important to detect and repair the heating pipe leakage problem in time. Through the detection methods and repair steps introduced in this article, you can quickly locate and solve the water leakage problem. At the same time, usually do a good job of preventive measures can effectively reduce the occurrence of heating pipe leakage.