On cold winter days, heat pipes bring us warmth and comfort. However, when there is a leakage problem in the heating pipeline, it not only affects the heating effect, but may also cause resource waste and safety hazards. So, how to find the leakage point of the thermal pipeline? Below, we will provide a detailed introduction to some effective methods for everyone.

1、 Observation method

Firstly, the location of the leakage point can be preliminarily determined through observation. Carefully inspect the ground, walls, and other areas around the thermal pipeline to see if there are any signs of moisture or water seepage. If the ground in a certain area is always damp or there are obvious water stains on the walls, it is likely that there is a leakage point near that area.

Meanwhile, pay attention to the connections, valves, and other parts of the thermal pipeline. These places are prone to water leakage due to their complex connections. If water droplets are found leaking out of the connection or if there is moisture around the valve, these areas should be inspected carefully.

2、 Listening method

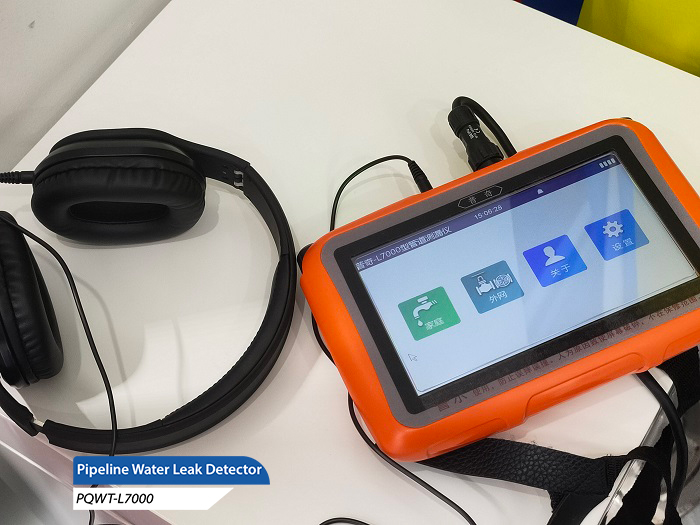

Listening to sound is a commonly used method for finding water leakage points. Use a professional pipeline leak detector or a simple stethoscope to listen along the direction of the thermal pipeline.

When a heat pipe leaks, it will make a specific sound. The sound at the leakage point is usually loud and clear, while the sound gradually decreases away from the leakage point. By listening to the sound and changes of the pipeline leak detector, the location of the leak point can be roughly determined.

It is best to choose a quiet environment when using a pipeline leak detector to listen for the sound of water leakage more accurately. At the same time, attention should be paid to distinguishing the interference of other noises, such as vehicle driving sound, machine operation sound, etc.

3、 Stress testing method

The pressure testing method is a relatively accurate way to locate water leakage points. Firstly, close all valves of the thermal pipeline, and then use professional pressure testing equipment to pressurize the pipeline.

Observe the changes in pressure during the pressurization process. If the pressure drops rapidly, it indicates that there is a leakage problem in the pipeline. At this point, you can gradually open each valve and observe the changes in pressure. When a certain valve is opened, the pressure drop significantly accelerates, indicating that there may be a leakage point in the pipeline connected to that valve.

4、 Thermal imaging method

Thermal imaging is a method of using infrared technology to locate water leakage points. When a thermal pipeline leaks, the temperature around the leak point will be different from the normal area.

Using a thermal imaging device to scan thermal pipelines can quickly and accurately identify areas of abnormal temperature, thereby determining the location of water leakage points. Thermal imaging is suitable for various complex environments and can be used for detection without damaging pipelines.

5、 Professional testing company

If none of the above methods can accurately locate the leakage point, or if you are unsure about your own testing results, you may consider hiring a professional testing company for testing.

Professional testing companies usually have advanced testing equipment and rich experience, which can quickly and accurately find the leakage point. They will use a combination of multiple testing methods based on specific circumstances to ensure the accuracy of the test results.

In short, when there is a leakage problem in the thermal pipeline, do not panic. You can use methods such as observation, listening, pressure testing, thermal imaging, etc. to find the leakage point. If you are unable to solve the problem yourself, promptly hire a professional testing company for inspection and maintenance to ensure the normal operation of the thermal pipeline and bring warmth and comfort to our winter life.