The pipeline system is a crucial component in infrastructure such as water supply, heating, and gas supply. However, over time, these pipelines may experience aging or damage, leading to leaks. Not only will it cause resource waste, but it may also bring inconvenience and even safety hazards to people's lives. Therefore, timely and accurate detection of leakage points in pipelines has become particularly important. At this point, the pipeline leak detector plays a crucial role.

1、 Introduction to pipeline leak detector

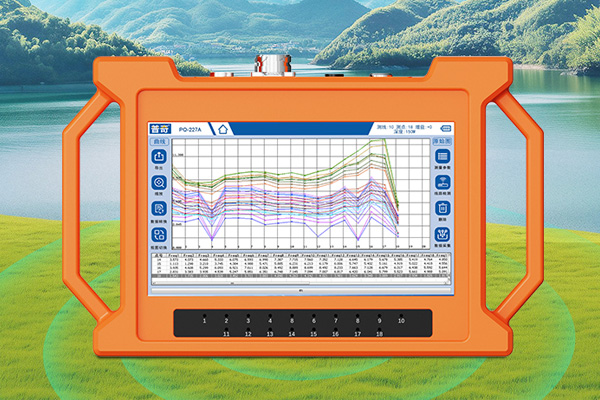

Pipeline leak detector is a specialized equipment designed to detect leaks in underground or concealed water pipes, gas pipes, and other pipelines. It uses different technical methods to locate the specific location of the leak, thereby helping maintenance personnel quickly solve the problem.

2、 Working principle

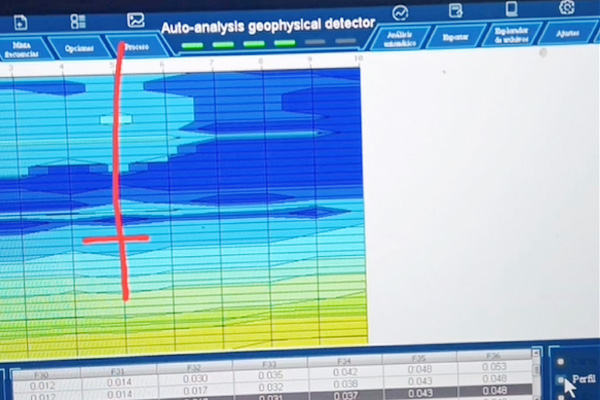

1. Acoustic/vibration method: This is one of the most commonly used detection methods. When water or other fluids leak from a damaged area, they produce specific frequencies of sound or small vibrations. The leak detector can capture this sound signal and enhance it through an amplifier before transmitting it to the operator. The location of the leak can be roughly determined based on changes in sound intensity. In addition, some advanced models are equipped with headphones and visual displays to facilitate users' more intuitive understanding of data information.

2. Gas tracking method: For certain types of pipelines (such as natural gas pipelines), gas tracking methods will be used for detection. This method first requires injecting a harmless and easily detectable gas (such as helium) into the pipeline. Then use instruments specifically designed to sense changes in gas concentration along the pipeline path. Once an abnormal increase in gas concentration is detected in a certain area, it indicates that there may be a leakage problem.

3. Temperature measurement method: The use of thermal imaging technology is also an effective way to detect pipeline leaks. When liquid flows out, the temperature of its surrounding environment usually changes. By capturing and analyzing images with an infrared camera, staff can identify areas of abnormal temperature and pinpoint potential sources of leakage.

4. Pressure testing: In addition to the above-mentioned techniques of directly finding leakage points, pressure testing will also be used when installing new pipelines or regularly inspecting old pipelines. First, close all outlet valves to create a closed space inside the pipeline, then gradually increase the internal pressure to a certain level and maintain it for a period of time. If a pressure drop rate exceeding the normal range is observed during this period, it may indicate the presence of unsealed connection points or other forms of defects.

3、 Application scenarios

-Maintenance of urban water supply network

-Monitoring of Cooling Circulation System in Industrial Production Process

-Security Management of Natural Gas Transmission Network

-Efficiency evaluation of farmland irrigation system

-Troubleshooting of household water facilities

4、 Conclusion

With the development of science and technology, modern pipeline leak detectors have achieved higher accuracy and a wider range of applications. They not only greatly improve work efficiency and reduce economic losses caused by pipeline leaks, but also contribute to ensuring public safety. In the future, with the continuous emergence of new materials and technologies, we believe that the field of pipeline leak detection will usher in more innovation and development.