In today's accelerating urbanization, the layout and maintenance of underground pipelines have become an important part of urban infrastructure construction and management. Whether it is electric power, communication, water supply and drainage or gas pipelines, their accurate detection and localization is of great significance to guarantee the safety of urban operation and improve the maintenance efficiency, and the selection and use of Pipe Cable Locator, as a professional tool in this field, is directly related to the accuracy and efficiency of the detection results. In this paper, we will discuss how to scientifically select the applicable Pipe Cable Locator from multiple dimensions.

First, clear detection needs, determine the scope of application

First of all, to define their own detection needs is the premise of choosing Pipe Cable Locator. Different industries and projects have different requirements for the accuracy, depth and type of pipe line detection. For example, the power industry may need to focus on the identification and location of high-voltage cables, while the water supply and drainage industry may focus more on the detection of non-metallic pipes. Therefore, when choosing a detector, be sure to understand its scope of application to ensure that the selected instrument can meet the actual detection needs.

Comparison of testing methods, the pursuit of simplicity and efficiency

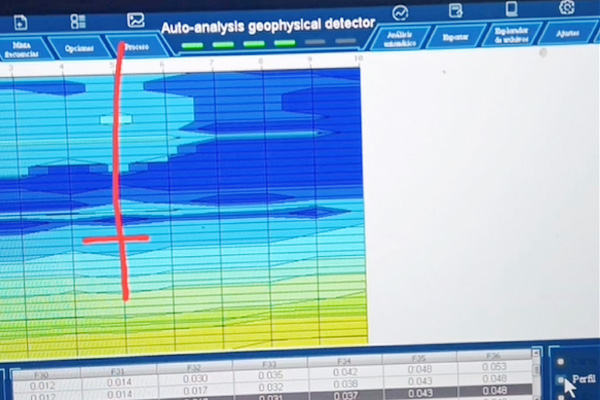

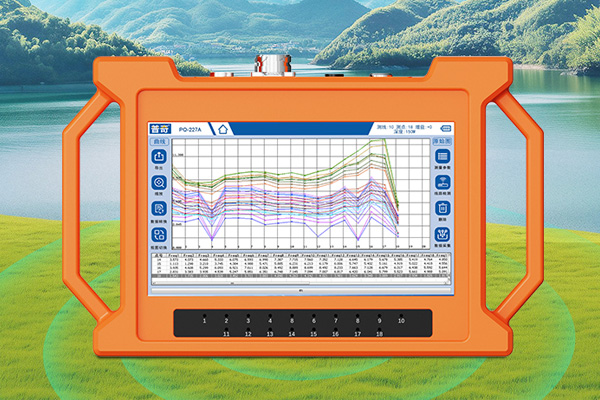

The testing methods of Pipe Cable Locator are mainly divided into electromagnetic induction method and electromagnetic wave detection method (i.e. radar detection). Electromagnetic induction method is applicable to the detection of metal pipelines, with simple operation and low cost advantages; while electromagnetic wave detection method is not restricted by material, can detect a variety of pipelines, including non-metallic, but the cost is relatively high. In the selection, should be based on the detection of the object of the material, the depth of burial and other factors to consider, choose the test method is more simple, efficient detector.

Third, assess the functional performance to ensure that it meets the needs

In addition to the test method, the functional performance of the detector is also a key factor in the selection. Focus on its ability to detect depth, accuracy, anti-interference ability and other aspects of their own needs. For example, for projects that require precise measurement of pipeline depth, you should choose a detector with high-precision bathymetry; while operating in complex environments, you need to pay attention to whether its anti-interference ability is strong enough.

Fourth, check the configuration of the accessories to ensure that complete and practical

The completeness of the accessory configuration is also a part of the selection of the detector can not be ignored. For example, clamps and other accessories in the dense area of cable detection can significantly improve detection efficiency; and rechargeable batteries help reduce the cost of long-term use. Therefore, when choosing a detector, you should double-check whether the configuration of its accessories is complete and practical to meet the detection needs of different scenarios.

Fifth, pay attention to instrument upgrades and compatibility

With the continuous progress of technology, Pipe Cable Locator is also constantly updated. Therefore, when choosing the instrument should also pay attention to the upgrade potential and compatibility. A detector that can be upgraded at any time to adapt to new technologies and new needs will be more valuable in the long run; at the same time, a wide range of receiving and transmitting frequencies will also help to expand the scope of detection and use of the instrument.

Conclusion

In summary, the scientific selection of a suitable Pipe Cable Locator requires a multidimensional approach. Defining detection needs, comparing test methods, evaluating functionality, checking accessory configurations, and focusing on upgrades and compatibility are all essential steps. Only in this way can we ensure that the selected detector can maximize its performance in practical applications and provide strong protection for the safe operation and maintenance of urban underground pipelines.