Water leakage is a common but difficult problem to deal with in modern construction and municipal engineering. Traditional water leakage detection methods often rely on visual observation or dismantling walls and floors for inspection. This method is not only time-consuming and labor-intensive, but also has significant destructive power. With the advancement of technology, water pipe detectors have emerged as a non-destructive detection tool, greatly improving work efficiency and accuracy.

Working principle of water pipe detector

The working principle of water pipe detector is mainly based on technologies such as sound waves, infrared radiation, and pressure testing. These technologies enable detection equipment to accurately locate water leakage points, reducing repair workload and costs.

1. Acoustic detection technology: This is one of the most commonly used leak detection techniques. By sending sound wave signals, the detection device can capture the sound wave reflection generated by water leakage, thereby determining the location of the water leakage point. Acoustic detection technology is applicable to various pipeline systems, including water supply, drainage, HVAC systems, etc. in residential, commercial buildings, and industrial facilities.

2. Infrared detection technology: The infrared leak detector uses infrared technology to detect whether the pipeline is leaking. This instrument can quickly and accurately locate the leakage point, especially suitable for leak detection of metal pipelines. Infrared detection technology has the advantages of non-contact and non-destructive testing, but its application range is relatively limited.

3. Pressure testing technology: Pressure testing technology detects water leakage by monitoring pressure changes inside the pipeline. When there is a leak in the pipeline, the pressure will change, and the detection equipment can capture this change to determine the location of the leak point. This technology is particularly suitable for leak detection in municipal water supply networks and underground pipelines.

Application scenarios of water pipe detector

Water pipe detectors are widely used in various applications, including but not limited to the following fields:

1. Building piping system: water supply, drainage, HVAC systems, etc. for residential, commercial buildings, and industrial facilities. The pipelines in these systems are complex and dense, and once water leakage occurs, it is often difficult to detect. The water pipe detector can quickly and accurately locate the leakage point, avoiding structural damage and property damage caused by leakage.

2. Municipal water supply network: The maintenance and monitoring of urban water supply pipelines and drainage systems are important components of municipal engineering. Water pipe detectors can help quickly detect and repair underground water leakage problems, ensuring the stability and safety of urban water supply.

3. Underground pipelines: The leakage problem of underground pipelines not only leads to resource waste, but also may cause safety hazards such as ground collapse. Water pipe detector can detect buried pipelines, promptly identify and repair leakage points, and avoid potential safety risks.

4. Waterproof engineering testing: such as testing the waterproof layer of buildings such as basements, tunnels, and subway stations. The leakage problem of waterproof layer will seriously affect the structural safety and service life of buildings. The water pipe detector can detect water leakage in the waterproof layer and take timely measures to repair it.

Selection and Use of Water Pipe Detector

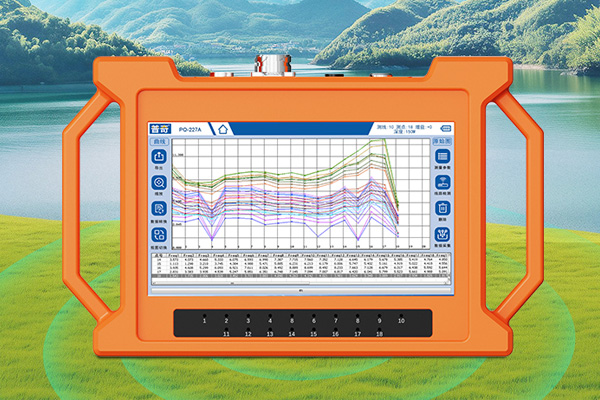

When choosing a water pipe detector, multiple factors need to be considered, including detection accuracy, usage cost, and ease of operation. Different devices have different characteristics and applicability, and users need to choose according to their actual situation.

When using a water pipe detector, the following steps need to be followed:

1. Preparation: Adjust the instrument to its optimal state to ensure its sensitivity is high enough; Familiar with the usage of the instrument and understand the functions of each button and knob.

2. Identify the location of water leakage: Based on the waterway diagram or experience, determine the possible location of water leakage, such as the position of water pipes, heating, air conditioning and other equipment.

3. Parameter setting: Adjust the parameters of the instrument according to the detection environment, such as volume, distance, and direction.

4. Start detection: Listen carefully or observe the instrument's prompt signals in areas where there may be water leakage, and look for abnormal sounds or signals.

5. Record data: Timely record the instrument's data and the location of the prompt signal for later analysis of water leakage.

Market Status and Development Trends of Water Pipe Detectors

There are currently various types of water pipe detectors on the market, including ultrasonic leak detectors, infrared leak detectors, electronic listening sticks, etc. These devices have their own characteristics and are suitable for different detection environments and needs.

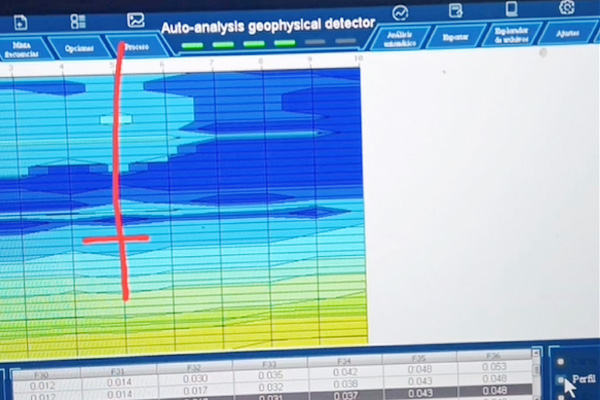

With the continuous advancement of technology, the accuracy and reliability of water pipe detectors are also constantly improving. In the future, water pipe detectors will develop towards greater intelligence, portability, and multifunctionality. For example, some advanced water pipe detectors have integrated multiple detection functions, such as sound waves, infrared, pressure and other technologies, which can adapt to different detection environments and needs. Meanwhile, with the development of IoT technology, water pipe detectors will also achieve remote monitoring and intelligent warning, further improving the efficiency and accuracy of water leakage detection.

In short, water pipe detectors play a crucial role in modern architecture and municipal engineering. By using these devices correctly, we can quickly and accurately detect and solve water leakage problems, avoiding structural damage and property losses caused by water leakage. At the same time, we also need to constantly pay attention to the development of technology and changes in the market, choose the water pipe detector that suits us, and improve work efficiency and accuracy.