Pipeline leak detector is an instrument specifically designed to detect and locate leakage points in water pipes, water supply systems, or other liquid delivery systems. Its importance lies not only in timely detection and repair of water leakage problems to prevent water resource waste, but also in protecting the structural safety of buildings and avoiding water damage. This article will provide a detailed introduction to the performance characteristics of pipeline leak detector for reference.

1、 Working principle

The pipeline leak detector mainly works based on acoustic principles. When water flows out of cracks or holes in pipelines, a specific frequency of sound is produced. These sounds will propagate along the pipeline and be transmitted to the ground through the soil. The pipeline leak detector captures these sound signals through highly sensitive sensors and determines the location of the leak point through a built-in analysis and processing system.

In addition to acoustic principles, some advanced pipeline leak detectors also utilize electromagnetic principles. By sending electromagnetic waves to underground pipelines and receiving reflected signals, the condition of the pipelines and the location of water leakage points can be determined. This method is particularly suitable for pipelines that are buried deep or have complex surrounding environments. The application of optical principles in water leakage detection is relatively limited, but in some special cases, optical detection methods can also play an important role. For example, by injecting fluorescent dye into the pipeline and observing the flow of the dye using optical equipment, the location of the leakage point can be determined.

2、 Performance characteristics

1. High sensitivity: Pipeline leak detectors typically use highly sensitive sensors that can capture weak sound signals and accurately locate water leakage points.

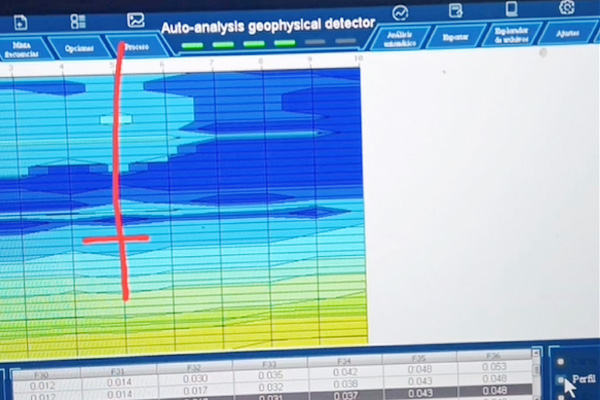

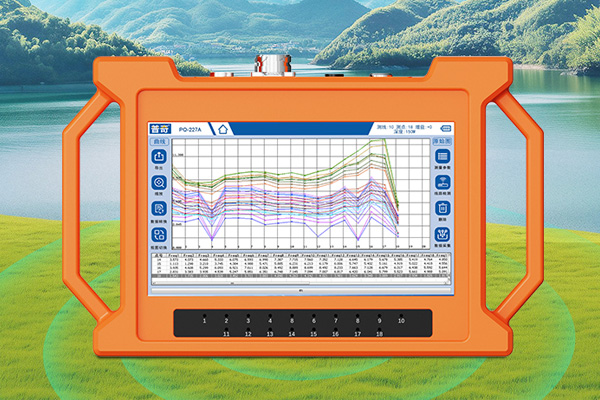

2. Multiple display modes: Pipeline leak detector has multiple display modes such as pointer, cursor, audio, and numbers, making it easy for users to intuitively understand the detection results. Some high-end instruments are also equipped with full-color touch screens, making operation more convenient.

3. Strong anti-interference ability: In complex underground environments, pipeline leak detectors need to have good anti-interference ability to eliminate interference from other noises and accurately capture leakage signals.

4. Data processing capability: The pipeline leak detector has a built-in high-speed and high-precision data processing system that can quickly analyze and process captured sound signals, improving detection efficiency and accuracy.

5. Portability: Pipeline leak detectors are usually small in size, light in weight, and easy to carry and use in the field. This enables inspectors to conduct rapid testing in various environments.

6. Multifunctionality: In addition to detecting leakage points, some pipeline leak detectors also have other functions, such as measuring pipeline pressure, flow rate, etc., providing users with more comprehensive pipeline information.

3、 Application examples

Pipeline leak detectors are widely used in residential, commercial, municipal, and industrial fields. In residential and commercial buildings, pipeline leak detectors can be used by inspectors to quickly locate water pipe leaks in houses, apartments, and commercial facilities, and repair them in a timely manner to avoid water damage. In municipal engineering, pipeline leak detectors are used to detect and maintain urban water supply systems, preventing large-scale water resource losses. In industrial facilities, pipeline leak detectors are used to monitor and maintain high-pressure and high flow industrial pipeline systems to ensure production safety.

4、 Precautions for use

1. Follow the instructions: When using the pipeline leak detector, strictly follow the manufacturer's instructions to avoid accidental operation that may cause damage to the instrument or inaccurate test results.

2. Regular inspection and calibration: To ensure the accuracy of the pipeline leak detector, it should be checked and calibrated regularly. This includes checking the sensitivity of sensors, battery level, and overall performance of the instrument.

3. Pay attention to environmental noise: During the detection process, attention should be paid to eliminating the interference of environmental noise. For example, in noisy environments, active noise reduction can be used to improve the clarity of listening.

4. Instrument protection: Pipeline leak detector is a precision instrument that should be protected during use. Avoid exposing it to harsh environments such as high temperatures, humidity, or strong magnetic fields.

Pipeline leak detectors play an important role in the field of water leakage detection due to their high sensitivity, multiple display modes, strong anti-interference ability, data processing capability, and portability. By using and maintaining pipeline leak detectors reasonably, we can promptly detect and repair water leakage problems, protect property safety, and save water resources.