In daily life and industrial production,leakage problems are like hidden"monsters"that occasionally cause trouble.Whether it's wall mold and floor deformation caused by water pipe leaks in households,or safety hazards and resource wastage triggered by leaks in large buildings and underground pipelines,they all cause considerable headaches.Pipeline leak detectors,akin to capable assistants with"X-ray vision,"can accurately pinpoint leakage points,providing crucial support for resolving leakage issues.

I.The Working Principles of Pipeline Leak Detectors

Acoustic Principle:Many pipeline leak detectors operate based on the acoustic principle.When a water pipe leaks,the water ejected from the damage point produces friction with the pipe wall and surrounding media,emitting specific frequency sounds.These sounds propagate through media such as pipes and soil.Acoustic leak detectors equipped with highly sensitive microphones can capture these faint leakage sound signals and convert them into electrical signals.Through amplification,filtering,and other processing of the signals,they are ultimately presented in an intuitive manner on the instrument's display screen,aiding operators in judging the location and severity of the leakage.For instance,in underground water supply networks of some cities,inspection personnel use acoustic leak detectors to detect along the pipeline routes,determining leakage points by listening to and analyzing sound signals.

Infrared Thermography Principle:This principle utilizes temperature differences on object surfaces for imaging.When a leakage occurs,due to factors such as water evaporation,the surface temperature of the leakage area differs from that of surrounding dry areas.Infrared thermography leak detectors can detect these subtle temperature changes and convert them into visual thermal images.In thermal images,areas with abnormal temperatures may indicate leakage points.This method is suitable for detecting regions that are difficult to observe directly,such as inside walls and ceiling voids.For example,in building inspections,for walls suspected of leakage,using an infrared thermography camera to scan can clearly show the temperature distribution on the wall surface,quickly locking down potential leakage locations.

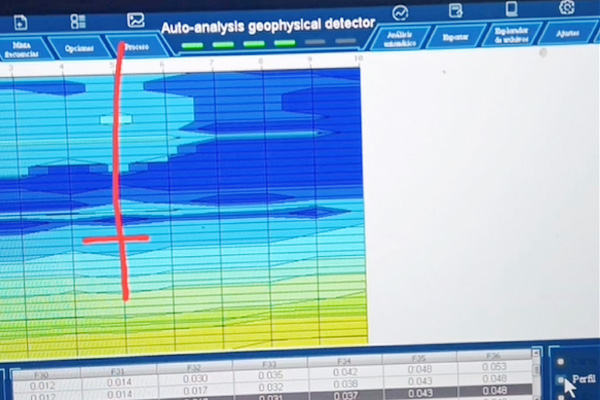

Electromagnetic Wave Detection Principle:Pipeline leak detectors based on the electromagnetic wave detection principle emit electromagnetic waves of specific frequencies into the ground or objects under inspection.When electromagnetic waves encounter different media(e.g.,dry soil vs.soil containing water),their reflection,scattering,and other characteristics change.The instrument receives and analyzes these altered electromagnetic wave signals to determine whether there is leakage underground and its approximate location.In the underground pipeline inspections of some large industrial parks,this method is often used for rapid screening of large areas for potential leakage hazards.

II.Types of Pipeline Leak Detectors

Portable Leak Locators:These instruments are compact and lightweight,easy to carry and operate,suitable for leakage detection in households and small commercial premises.Typically designed based on the acoustic principle,they come with simple and user-friendly interfaces and functions.Inspectors can hold the instrument and detect along pipeline routes or in suspected leakage areas.For example,when water pipe leakage is suspected in a household,users can use a portable leak locator to detect walls,floors,and other locations,quickly finding leakage points and preventing problems from escalating.

Vehicle-Mounted Leak Localization Systems:Mainly used for detecting large-scale pipeline systems such as urban underground water supply networks.Installed on vehicles,these systems emit detection signals underground and receive feedback signals through onboard equipment.As the vehicle travels,it can rapidly inspect longer stretches of pipelines.Vehicle-mounted leak localization systems generally combine multiple detection technologies,such as acoustics and electromagnetic wave detection,to enhance detection accuracy and efficiency.Some large cities'water companies regularly use vehicle-mounted leak localization systems to inspect underground water supply networks,promptly identifying and repairing leakage points to reduce water resource wastage.

Embedded Leak Sensors:This type of instrument is usually installed around pipelines or within areas needing monitoring for real-time monitoring of leakage occurrences.Upon detecting leakage,the sensor immediately sends signals to notify relevant personnel.Embedded leak sensors are commonly used in places sensitive to leakage hazards,such as data centers and computer rooms,enabling the timely identification of leakage risks to prevent damage to critical equipment.

III.Application Scenarios of Pipeline Leak Detectors

Households and Commercial Buildings:In households,kitchens,bathrooms,and other frequently used water areas are prone to water pipe leaks.Pipeline leak detectors can help homeowners quickly locate leakage points for timely repairs,avoiding furniture damage,wall mold,and other issues.In commercial buildings like malls and hotels,leakage can disrupt normal operations and cause significant economic losses.Using pipeline leak detectors can swiftly pinpoint leakage locations,shortening repair time and minimizing impacts on business activities.

Industrial Facilities:Factories,refineries,and other industrial sites have complex pipeline systems,and the transported media may be corrosive or hazardous.Leakage can result in material loss and potential safety accidents.Pipeline leak detectors can quickly and accurately locate leakage points without disrupting production,ensuring the safe operation of industrial facilities.

Municipal Engineering:Urban underground water supply networks,drainage networks,and other municipal facilities are vast in scale.The application of pipeline leak detectors in municipal engineering can promptly detect leakage points in pipeline networks,reducing water resource wastage and preventing issues such as road collapses due to leakage.Additionally,for inspections of urban sewage treatment systems,pipeline leak detectors can help determine if sewage leakage exists,preventing environmental pollution.

IV.How to Choose the Right Pipeline Leak Detector

Inspection Environment:For indoor spaces such as households or small offices,portable leak locators may suffice,due to their ease of operation and suitability for limited spaces.For large-scale underground pipeline network inspections,vehicle-mounted leak localization systems are more appropriate,capable of rapidly covering larger areas.

Inspection Objects:Different materials and types of leakage situations require different detection instruments.For example,for metal pipelines,some pipeline leak detectors based on electromagnetic induction principles may work better;for plastic pipelines,acoustic or infrared thermography instruments may be more suitable.Furthermore,for detecting minute leaks,instruments with higher sensitivity are needed.

Budget:Pipeline leak detectors vary widely in price,ranging from portable simple instruments costing a few thousand yuan to high-end vehicle-mounted systems priced at several hundred thousand yuan.When selecting,it is essential to comprehensively consider actual needs and budget,ensuring that the detection requirements are met without overspending.

With the continuous development of technology,pipeline leak detectors are constantly being upgraded,with improved detection accuracy and efficiency.In the future,pipeline leak detectors will play crucial roles in more fields,providing more convenient and efficient solutions to leakage problems.Whether ensuring the comfort of household life or maintaining the normal operation of urban infrastructure,pipeline leak detectors will remain indispensable tools.