Pipeline leakage detection is an important step in ensuring the normal operation of the water supply system, reducing water resource waste, and avoiding potential damage. The following is the detailed process of pipeline leakage detection, covering the entire process from preliminary preparation to final determination of the leakage point and repair.

1、 Preliminary preparation

1. Information collection:

1.1 Collect relevant information on the pipeline system, including pipeline drawings, materials, diameters, burial depths, and other related information.

1.2 Understand the historical maintenance records and current operating status of the pipeline system.

2. Equipment preparation:

2.1 Prepare necessary testing tools and equipment, such as pipeline leak detectors, pipeline detectors, conductivity pens, pressure pumps, etc.

2.2 Ensure that all devices are functioning properly and have sufficient batteries for use during the testing process.

3. Personnel preparation:

3.1 Arrange experienced testing personnel to ensure they are familiar with the testing process and operating procedures.

3.2. Reasonably allocate personnel based on the size and complexity of the detection area.

2、 On site inspection

1. Pipeline detection:

1.1 Use a pipeline detector to determine the accurate direction and burial depth of the pipeline.

1.2 In areas where the direction of the pipeline is uncertain, use a detector to scan and mark the planar position of the pipeline.

2. Initial listening leakage:

2.1 Starting from the end and exposed parts of the pipeline, use a leak detector for direct contact leak detection.

2.2. Pay attention to distinguishing between the sound of water passing through the pipeline and the sound of water leakage, which is usually manifested as a whistling or whistling sound.

3. Ground listening leakage:

3.1 Conduct ground listening along the pipeline at the suspected leaking section.

3.2. Use a leak detector to move forward in a "Z" shape on the ground above the pipeline, ensuring that no possible leakage points are missed.

3.3. Record and mark any suspected water leakage sounds heard for subsequent analysis.

4. Auxiliary detection:

4.1 Use a conductivity pen to test the conductivity of the effluent water and eliminate the possibility of leakage in the circulating water pipe.

4.2. Conduct a pressure test on the suspected water leakage area, observe the changes in the pressure gauge, and determine whether there is water leakage.

3、 Identify the leakage point

1. Sound analysis:

1.1 Analyze the suspected water leakage sounds recorded during ground listening, and compare the differences in sound intensity and pitch at different points.

1.2. Determine the approximate location of the water leakage point based on the changes in sound.

2. Location verification:

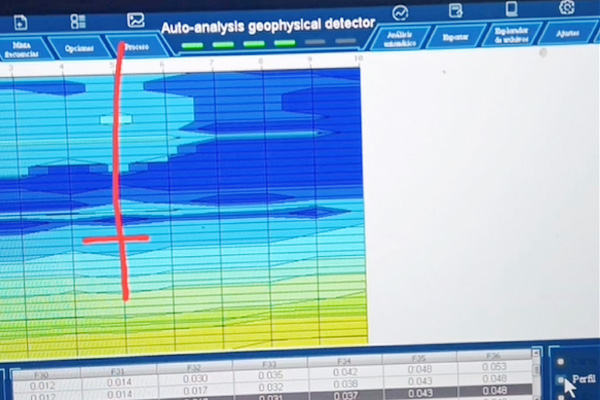

2.1 Use the "location" mode of the pipeline leak detector to further verify suspected water leakage points.

2.2. Extend the inspection and comparison from the suspected leakage point to both ends, and determine the point with the strongest signal as the leakage point.

3. Marking and recording:

3.1 Mark the accurate location of the leakage point on the pipeline drawing.

3.2. Record relevant information about the leakage point, such as depth, material, leakage situation, etc.

4、 Repair and acceptance

1. Develop a repair plan:

1.1 Develop a suitable repair plan based on the location and condition of the leakage point.

1.2 Prepare necessary repair materials and tools.

2. Implement repairs:

2.1 Close the water supply valves in the relevant areas to ensure safety during the repair process.

2.2. Excavate the soil around the leakage point and expose the leaking pipeline.

2.3 Repair according to the repair plan, such as replacing pipelines, repairing cracks, etc.

3. Acceptance and testing:

After the repair is completed, conduct a pressure test on the pipeline to ensure that the leakage problem is resolved.

3.2. Observe and record test data to ensure that the pipeline system resumes normal operation.

3.3 Clean up the site and restore the soil and landscape around the pipeline.

5、 Subsequent maintenance

1. Regular inspection:

1.1 Regularly inspect and maintain the pipeline system to ensure timely detection and resolution of potential issues.

1.2. Record the results of each inspection and maintenance records for future reference.

2. Strengthen protection:

2.1 Necessary protective measures shall be taken for the pipeline system, such as installing insulation layers, anti-corrosion treatment, etc.

2.2. Avoid heavy construction or stacking heavy objects above the pipeline to reduce damage to the pipeline.

Through the above process, it is possible to comprehensively and accurately detect and locate pipeline leakage points, promptly repair them, and ensure the normal operation and safety of the water supply system.