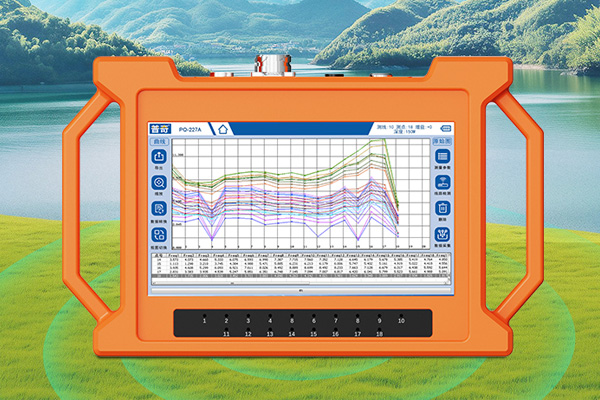

Pipeline leakage detector is an efficient and accurate detection tool widely used in modern pipeline maintenance. To ensure accurate and reliable detection results during use, the following points should be noted when using a pipeline leak detector:

1、 Check the status of the instrument

Before operation, the status of the pipeline leak detector should be checked first. Ensure that the battery is fully charged, the sensor sensitivity is high, and the display screen is clear and undamaged. In addition, it is necessary to check whether the connecting wires, headphones, and other accessories of the instrument are intact to avoid affecting the detection effect.

2、 Understand the functions of the instrument

Before operating the pipeline leakage detector, carefully read the user manual to understand the various functions, operating methods, and precautions of the instrument. To avoid detection failure or instrument damage caused by improper operation.

3、 Choose suitable environmental conditions

The use of pipeline leak detectors is greatly affected by environmental conditions. During operation, attention should be paid to avoiding strong noise sources such as mechanical equipment, traffic arteries, etc., to avoid interfering with the detection results. At the same time, suitable temperature and humidity conditions should be selected for testing to ensure the stability and accuracy of the instrument.

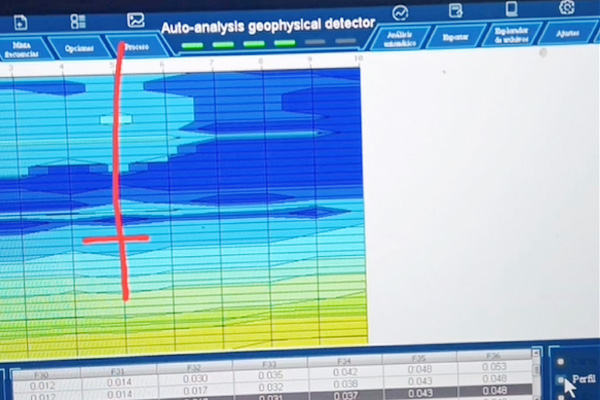

4、 Locate and investigate water leakage points

When locating the leakage point, it should be checked one by one along the direction of the pipeline. When the detector emits an alarm signal, the sound characteristics should be carefully identified and analyzed in combination with the signal strength on the display screen. For suspected water leakage points, multiple retests should be conducted to confirm their accuracy. In addition, attention should be paid to distinguishing other interference signals, such as water flow sound, gas leakage sound, etc.

5、 Pay attention to safe operation

When operating a pipeline leak detector, safety should be taken into account. Avoid testing in high-pressure, high-temperature, or toxic environments. At the same time, relevant safety regulations should be followed, necessary protective equipment should be worn to ensure personal safety.

6、 Understand pipeline information

Before starting the inspection, it is crucial to understand the burial direction, material, and burial depth of the pipeline to locate the leakage point. These pieces of information can help narrow down the detection range and improve detection efficiency.

7、 Master detection skills

For users who are using the pipeline leak detector for the first time, they can first place the sensor probe on the water tap pipeline or nearby ground, and experience the sound wave of the leak from the earpiece or headphones, in order to better identify the leak signal.

When detecting leakage points, a vibration sensor probe can be directly used to detect on hard ground, while on soft soil or lawn, a metal plug rod should be screwed at the bottom of the probe and inserted into the soil for detection.

3. If a suspected water leakage point is found, for caution, do not immediately determine that the point is the location of the leak. It is best to drill several deep holes near the ground and then insert a listening rod into the listening area to compare the sound volume of each point. This method of positioning is more accurate.

8、 Regular maintenance and upkeep

As a precision instrument, the pipeline leakage detector requires regular maintenance and upkeep. After use, the surface of the instrument should be promptly cleaned of dirt and dust to maintain its cleanliness. At the same time, the performance and accuracy of the instrument should be regularly checked, and if there are any problems, they should be repaired or replaced in a timely manner.

9、 Review and Confirmation

After the inspection is completed, a re examination can be conducted to ensure the accuracy of the leakage point. If necessary, multiple inspections can be conducted around the leakage point to eliminate errors.

In summary, when using a pipeline leak detector, attention should be paid to the instrument status, operating procedures, environmental conditions, positioning and troubleshooting, safe operation, pipeline information, detection techniques, maintenance and upkeep, as well as re inspection and confirmation. Only by strictly adhering to these precautions can the accuracy of test results and the stability of instruments be ensured, providing strong support for water management.