Pipeline leak detector is a device used to detect pipeline leakage problems, widely used in industrial production and environmental protection. It determines the location and degree of leakage by measuring pressure differences, acoustic vibrations, temperature changes, or the escape of specific gases in the pipeline. This article will provide a detailed introduction to the working principle and related technologies of pipeline leak detector.

1、 Principle of Leak Detection Based on Acoustic Wave Technology

One of the most commonly used working principles of pipeline leak detectors is acoustic technology. When a pipeline leaks under a certain pressure, the leakage point will vibrate. This vibration is mainly composed of two parts: one is the vibration generated by the water flow at the leakage point and the friction with the pipe wall; The second is the additional vibration caused by the leakage itself. These vibrations propagate along the pipe wall and are also transmitted to surrounding media such as soil or air.

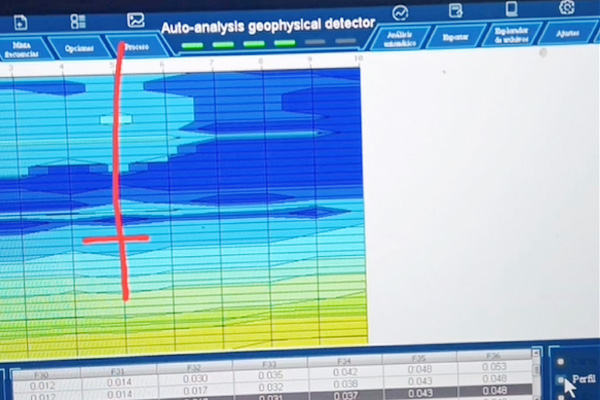

The leak detector receives these vibration signals through highly sensitive sensors and converts them into electrical signals for processing and analysis. The sound wave signal captured by the sensor is amplified and filtered before being transmitted to the display device. The staff can determine the location of the leakage point by comparing the signal strength between different points. Generally speaking, the closer to the leakage point, the stronger the signal; The farther away from the leakage point, the weaker the signal.

2、 Leak detection principle based on pressure difference

Pipeline leak detector can also be based on fluid mechanics and sensor technology to determine the location and degree of leakage by measuring pressure differences in the pipeline. When a pipeline leaks, the pressure inside the pipeline will change, and the pressure near the leak point will decrease. The core component of the leak detector, the pressure sensor, can detect this pressure change and convert it into an electrical signal to transmit to the control system.

The control system analyzes the characteristics of pressure differences and leaks based on the set parameters, and displays the results on the operation interface. At the same time, the control system can also set up an alarm system as needed to remind staff to take action. In addition, the pipeline leak detector can upload data to the computer system for further analysis. By comparing historical data, it can determine whether there are potential leakage hazards in the pipeline and develop reasonable preventive measures.

3、 Leak detection principle based on temperature changes

Water leakage can cause temperature changes in the surrounding environment, especially in underground pipelines. Therefore, the pipeline leak detector can also use an infrared thermal imager to scan the ground and identify the leaking area through temperature differences. Infrared thermal imagers can capture the temperature distribution on the ground, and the temperature at the leak point is usually different from other areas, which helps determine the location of the leak.

4、 Leak detection principle based on tracer gas

Another leakage detection method is to inject specific tracer gases (such as nitrogen, helium, etc.) into the pipeline, which will escape at the leakage point. Leak detectors use gas detectors to detect the concentration of tracer gases on the ground or near pipelines, in order to locate the leak point. This method is particularly suitable for leak points that are difficult to detect through sound waves or pressure differences.

5、 Principle of leakage detection based on electromagnetic signals

The pipeline leak detector can also send electromagnetic signals to the pipeline to detect the reflection and attenuation of the signals, thereby determining the integrity and leakage location of the pipeline. The electromagnetic detector sends and receives electromagnetic signals, analyzes the changes in the signals to locate the leakage point. This method is suitable for metal pipelines and can detect small leaks inside the pipeline.

6、 System performance requirements

The pipeline leak detector needs to consider the following requirements and performance during use:

1. Sensitivity: The leak detector needs to have sufficient sensitivity to detect small leakage signals.

2. Response speed: The leak detector needs to have the ability to respond quickly and detect and locate leaks early.

3. Accuracy: The leak detector needs to have high-precision measurement capabilities to ensure the accuracy of the leak location and degree.

4. Anti interference: The leak detector needs to resist external environmental interference to ensure the reliability of the measurement results.

5. Applicability: Leak detectors need to adapt to the characteristics of different pipeline materials and media, and have a wide range of applicability.

The pipeline leak detector can efficiently and accurately detect pipeline leakage problems through the above principles and technologies. In practical applications, it can become an important tool for pipeline safety management, helping to prevent accidents, reduce resource waste, and improve production efficiency. Whether it is sound wave technology, pressure differences, temperature changes, tracer gases, or electromagnetic signals, pipeline leak detectors provide strong support for pipeline maintenance and management with their unique advantages.