In daily life and industrial production, the transportation and use of water are ubiquitous. However, with the increase of service life, changes in geological conditions, and construction quality, pipeline systems are inevitably affected by water leakage problems. Water leakage not only causes a significant waste of water resources, but may also lead to a series of safety hazards and economic losses, such as ground collapse, structural damage to buildings, and high water bills. The emergence of high-precision pipeline leak detectors provides strong technical support for timely detection and resolution of water leakage problems.

A. Working principle

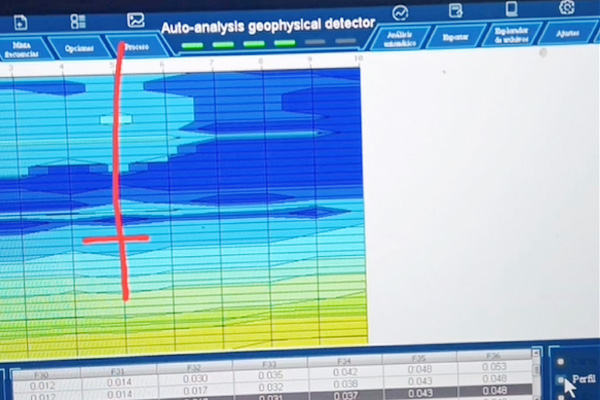

The high-precision pipeline leak detector mainly works based on acoustic principles. When water leaks in a pipeline, due to the pressure difference, the water flow will be ejected from the leak point and generate friction and impact with the surrounding medium, thereby producing a specific frequency of sound wave signal. These sound wave signals propagate in media such as pipelines and soil. High precision pipeline leak detectors capture these weak sound wave signals through high-precision sensors and convert them into electrical signals for amplification and processing. Advanced instruments adopt digital signal processing technology (DSP), which can perform complex operations such as filtering, noise reduction, and spectral analysis on the collected signals, effectively distinguishing between water leakage sound waves and environmental noise, accurately extracting characteristic information related to water leakage, and determining the location and approximate range of water leakage.

B. Core components

1. Sensor: It is the "ear" of the pipeline leak detector, and its sensitivity and frequency response range directly affect the ability to capture water leakage sound waves. High precision pipeline leak detectors are typically equipped with high-performance piezoelectric sensors or other advanced acoustic sensors, which can sensitively sense extremely weak sound wave vibrations and maintain good response characteristics over a wide frequency range, ensuring that no possible water leakage signals are missed.

2. Signal amplifier: responsible for amplifying the weak electrical signals collected by the sensor, so that the subsequent signal processing circuit can effectively analyze them. High quality signal amplifiers have the characteristics of low noise, high gain, and wide dynamic range, which can amplify signals while minimizing the introduction of noise, ensuring the authenticity and accuracy of signals.

3. Signal processor: This is the "brain" of the pipeline leak detector, responsible for the important task of digitizing, analyzing, and computing amplified signals. By using advanced DSP chips or specialized signal processing algorithms, it is possible to quickly and accurately perform spectral analysis, correlation analysis, filtering, and other operations on the signal, extract the characteristic parameters of the leakage signal, such as frequency, amplitude, phase, etc., and calculate the location information of the leakage point based on these parameters.

PQWT pipeline leak detector Products Recommended

PQWT-LDC Multi Sensors Outdoor

PQWT L7000High Quality Underground PipelineWater Leak Detection Device

PQWT-L50 Indoor Pipeline WaterLeak Detector

C. Key technical indicators

1. Sensitivity: An indicator that measures the minimum leakage signal strength that an instrument can detect. A high-sensitivity pipeline leak detector can capture weak sound waves of water leakage at longer distances or in more complex environments, and detect potential water leakage hazards in advance. Generally speaking, excellent high-precision pipeline leak detectors can detect acoustic signals generated by extremely small changes in water pressure, with sensitivity reaching several micropascals or even lower.

2. Resolution: Indicates the accuracy of the instrument in locating the location of water leakage. High resolution instruments can more accurately determine the specific location of water leakage points, reducing the workload of excavation and repair and the impact on the surrounding environment. Modern advanced pipeline leak detectors can achieve centimeter level or even higher positioning resolution by using high-precision sensors, optimized signal processing algorithms, and multi-sensor fusion technology. They can accurately locate leakage points in complex underground pipeline networks.

3. Detection range: refers to the maximum distance or area at which the instrument can effectively detect water leakage signals. The detection range is affected by various factors, such as sensor performance, pipeline material and burial depth, soil type and humidity, etc. High precision pipeline leak detectors can usually detect pipelines that are hundreds or even thousands of meters long under reasonable usage conditions, and can quickly screen the approximate location of the leak point in a large area, greatly improving detection efficiency.

D. Application scenarios

1. Urban water supply system: The urban water supply pipeline network is vast and complex. Once a leak occurs, it not only causes serious waste of water resources, but may also affect residents' normal water use. The high-precisionpipeline leak detector can regularly inspect the water supply pipeline, timely detect and repair leakage points, ensure the safe and stable operation of urban water supply, and save a lot of water resources and water supply costs.

2. Building water supply and drainage system: In various types of buildings, the problem of water leakage in water supply and drainage pipelines may lead to wall leakage, damp ground, and decoration damage, seriously affecting the functionality and aesthetics of the building. By using high-precision pipeline leak detectors, it is possible to conduct comprehensive inspections of water supply and drainage pipelines before delivery or during daily maintenance of buildings, promptly identifying and resolving potential water leakage hazards, and avoiding unnecessary economic losses and disputes caused to owners due to water leakage issues.

3. Industrial production field: Many industrial production processes cannot do without a large amount of water supply, such as chemical, pharmaceutical, power and other industries. Once an industrial pipeline system leaks, it may lead to serious consequences such as production accidents, equipment damage, and product quality decline. The high-precision pipeline leak detector can perform real-time monitoring and rapid detection of complex pipeline systems in industrial production environments, ensuring the continuity and safety of industrial production, and reducing production downtime losses and maintenance costs caused by water leakage accidents.

E. Advantages and limitations

1. Advantages

-High precision positioning: It can accurately locate the location of water leakage points, greatly reducing the time and cost of troubleshooting and repair, and improving maintenance efficiency.

-Non destructive testing: The testing task can be completed without the need for large-scale destructive excavation of pipelines or ground, maximizing the protection of the environment and facilities around the pipeline.

2. Limitations

-Affected by environmental factors: In noisy environments such as busy roads, construction sites, etc., background noise may interfere with the detection of water leakage signals and reduce the detection accuracy of instruments. In addition, factors such as soil type, moisture, and compaction can also affect the propagation of sound waves, thereby affecting the accuracy of detection results.

-High requirements for operators: using high-precision pipeline leak detectors requires operators to have certain professional knowledge and skills, be familiar with the operation methods of the instrument, signal analysis principles, and the basic situation of the pipeline system. Otherwise, they may not be able to correctly interpret the detection results or miss some important leakage signals.

-Limited detection depth: Although the detection depth of modern pipeline leak detectors is constantly improving, there may still be difficulties or inability to detect pipelines that are deeply buried underground or obstructed by other obstacles.

F. Future Development Trends

With the continuous advancement of technology, high-precision pipeline leak detectors will develop towards greater intelligence, multifunctionality, high precision, and portability.

1. Intelligence: With the help of artificial intelligence and machine learning technology, instruments will be able to automatically learn and recognize different types of leakage signal patterns, improving the accuracy and reliability of detection. At the same time, deep integration with the Internet of Things is achieved, enabling remote monitoring, data sharing, and automatic alarm functions, making pipeline leakage detection more convenient and efficient.

2. Multifunctionality: In addition to leak detection function, future instruments will integrate more pipeline detection functions, such as pipeline corrosion detection, pipeline internal imaging, etc., providing a one-stop solution for comprehensive evaluation and maintenance of pipeline systems.

3. High precision: Continuously improve the sensitivity and resolution of sensors, optimize signal processing algorithms, further enhance the accuracy of leak location, achieve early detection of smaller leaks, and minimize water resource waste and safety hazards.

4. Portability: Adopting the design concept of lightweight and miniaturization, the pipeline leak detector is more convenient to carry and operate, suitable for various complex detection environments such as narrow spaces, high-altitude operations, etc., improving the flexibility and efficiency of detection work.

As an advanced pipeline detection device, high-precision pipeline leak detector plays a crucial role in ensuring the rational utilization of water resources and maintaining the safe and stable operation of pipeline systems. With the continuous innovation and development of technology, it will show broader application prospects in future urban construction, industrial production and other fields, providing more efficient and accurate solutions to solve pipeline leakage problems.