Water pipe leakage is a common and urgent problem in households and public facilities. Leakage not only leads to wastage of water resources, but may also cause damage to building structures and even pose more serious safety hazards. In order to effectively detect and locate water leakage points, pipeline leak detectors have become an indispensable tool. This article will provide a detailed introduction to the usage of the pipeline leak detector, helping you quickly and accurately locate the leak point.

1、 Understand the working principle of the water leakage detector

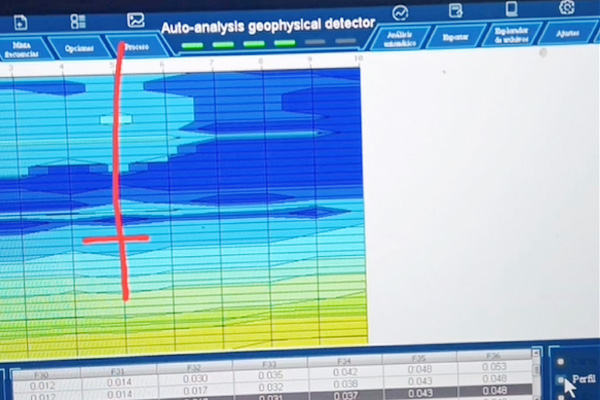

Pipeline leak detectors typically use physical phenomena such as sound, electromagnetic waves, or pressure waves to detect water leakage points. When a water pipe leaks, water flows out through cracks or holes, creating turbulence accompanied by specific sounds, vibrations, or pressure changes. The detection instrument captures these abnormal signals to locate the specific location of the water leakage. Common detection methods include acoustic wave detection, electromagnetic wave detection, and pressure detection.

2、 Preparation stage

Before using the pipeline leak detector, the following preparations need to be made:

1. Close the main water valve: Before conducting the test, be sure to close the main water valve to prevent water flow from interfering with the test results.

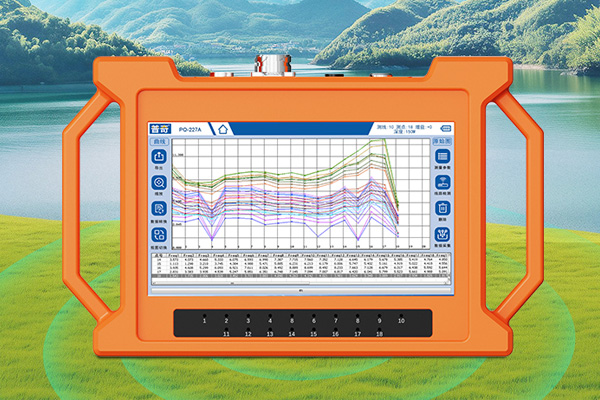

2. Prepare tools: Ensure that all necessary equipment such as pipeline leak detectors, sensors, headphones, recording tools, etc. are ready and check if their status is good.

3. Understand the pipeline layout: Based on the pipeline drawings, understand the layout, direction, and burial depth of the water pipeline, so as to more accurately locate the leakage point during inspection.

3、 Usage steps

The following are the basic steps for using pipeline leak detector:

1. Preliminary inspection: Conduct a preliminary inspection in the leaking area, and determine the approximate range of water leakage by observing or perceiving the damp area with the naked eye.

2. Sensor placement: Place the sound wave sensor or electromagnetic wave sensor of the detector on the surface of the suspected leaking pipeline. Ensure that the sensor is in close contact with the surface of the pipeline to better capture water leakage signals.

3. Turn on the detector: Connect the sensor and the detector host, turn on the power switch, and enter the detection mode. Set corresponding parameters such as sensitivity, frequency, etc. based on the model and function of the detector.

4. Monitoring and analysis: Wear headphones and carefully monitor the sound signals emitted by the detector. Determine the location of the water leakage point based on the strength of the signal and changes in sound quality. If the signal is enhanced, it indicates that it is close to the leakage point; If the signal weakens, it indicates that it is far away from the leakage point.

5. Mark the leakage point: Once the leakage point is preliminarily located, use a marking pen or label to mark it on the surface of the pipeline. This will help with the subsequent maintenance work.

6. Verification and repair: Conduct further verification near the marked leakage point to ensure accurate positioning. Once the leakage point is confirmed, repair work can be carried out. After the repair is completed, conduct another inspection to ensure that the water leakage issue has been thoroughly resolved.

4、 Precautions

When using pipeline leak detector, the following points should be noted:

1. Safety first: Ensure compliance with safety operating procedures during the testing process to avoid accidents such as electric shock and slipping caused by water leakage.

2. Eliminate interference: During the detection process, pay attention to changes in the surrounding environment, such as other interfering factors such as sound and vibration, to avoid interference with the detection results.

3. Keep the instrument clean: Clean the detector and sensor in a timely manner after use, keeping their surfaces clean and dry to extend their service life.

4. Professional operation: Although the operation of pipeline leak detector is relatively simple, it is recommended to have professionals or trained personnel perform the operation to ensure accuracy and safety.

Pipeline leak detector is a powerful tool for solving water leakage problems. By understanding its working principle, preparing well, following the usage steps, and paying attention to relevant matters, we can quickly and accurately locate the leakage point and carry out timely and effective repairs. This not only helps to save water resources and reduce maintenance costs, but also protects building structures and residential safety. I hope this article can provide you with valuable reference and assistance.