With the acceleration of urbanization, as an important part of urban infrastructure, the safe and stable operation of heat pipe network is directly related to the continuity of residential heating and industrial production. However, due to the aging of pipelines, construction quality, geological changes and other factors, water leakage of heat pipes occurs from time to time, which not only causes waste of water resources, but also may lead to safety accidents, affecting the normal operation of the city. Therefore, it is of great significance to adopt scientific and efficient leakage detection technology to find and repair the leakage points in time to ensure the safe operation of the heat pipe network. The following is a comprehensive set of solutions for heat pipe leakage detection.

I. Pre-preparation and preliminary assessment

1. Data collection: collect basic information such as design drawings, construction records and maintenance history of heat pipes, and understand key parameters such as pipe material, laying method and service life.

2. On-site investigation: Conduct on-site investigation of the suspected leakage area, observe whether there are wet marks on the ground, abnormal growth of vegetation, soil subsidence and other phenomena, and initially determine the possibility of water leakage.

3. Historical data analysis: analyze the past water leakage records, identify the high incidence of water leakage areas and time periods, and provide key directions for subsequent testing.

Second, the application of modern detection technology

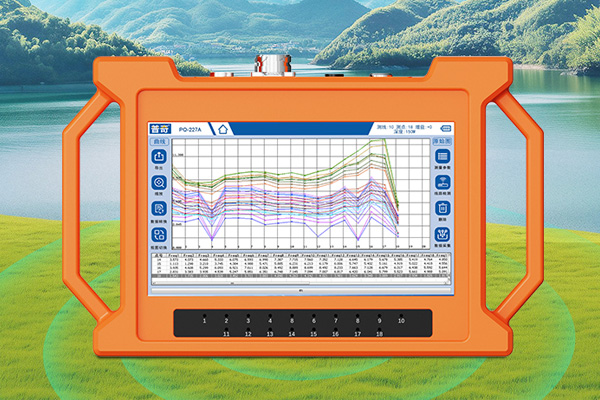

1. Acoustic wave detection technology: the use of sound wave signals generated by water leakage for localization. Including ground listening method, through the special listening stick or pipeline leak detector in the surface to capture the sound of water leakage; and pipe detection, through the robot or pipeline endoscope carrying sensors into the pipeline interior, direct detection of water leakage sound source.

2. Infrared thermal imaging technology: using the principle of heat dissipation at the leakage, the infrared thermal camera captures the temperature difference on the surface of the pipeline and quickly locks the leakage area.

3. Electromagnetic flow and pressure monitoring: install flow meters and pressure sensors upstream and downstream of the pipeline to monitor the flow and pressure changes, and abnormal changes are often indicative of water leakage.

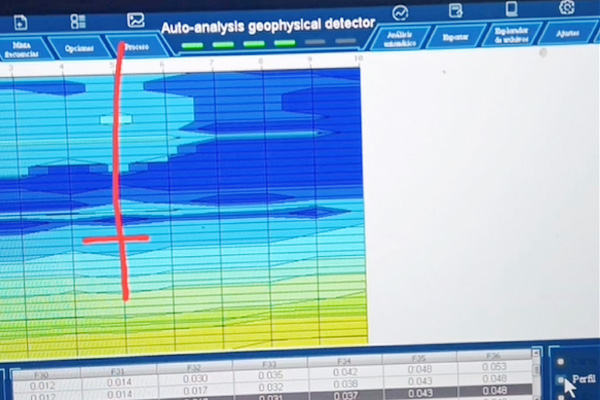

4. Radar and geo-radar technology: the use of electromagnetic wave propagation characteristics in different media, detecting the structural changes in the underground pipeline and its surrounding soil, and indirectly determine the location of water leakage.

Third, data analysis and precise location

1. Data integration: Integrate the data collected by various detection technologies, including but not limited to acoustic signals, infrared images, flow and pressure data.

2. Intelligent analysis: Using big data analysis, machine learning and other technologies, the collected data are analyzed in depth to improve the accuracy and efficiency of water leakage detection.

3. Three-dimensional modeling: Combined with the GIS geographic information system, establish a three-dimensional model of the heat pipe, visualize the spatial location of the leakage point, and facilitate the development of subsequent restoration programs.

Fourth, water leakage repair and subsequent management

1. Repair program development: according to the specific location of the leakage point, the condition of the pipeline and the surrounding environment, develop a scientific and reasonable repair program, such as excavation repair, non-excavation repair (such as pipe lining, winding repair) and so on.

2. Implementation of repair: organize professional construction teams to carry out water leakage repair according to the established program to ensure the quality of repair.

3. Follow-up monitoring and maintenance: After the completion of the repair, continuously monitor the stability of the leakage point, strengthen the daily maintenance and regular inspection of the pipeline, and prevent the occurrence of future leakage events.

V. Summary and Prospect

Heat pipe leakage detection is a systematic project that requires the comprehensive use of a variety of technical means, combined with scientific management methods, in order to achieve accurate and efficient leakage detection and repair. With the continuous development of the Internet of Things, artificial intelligence and other technologies, the future of heat pipe leakage detection will be more intelligent and automated, not only to warn of potential leakage risks in advance, but also to optimize the maintenance strategy, reduce the cost of operation and maintenance, and contribute to the sustainable development of the city.